The waste material in a landfill behaves as a complex porous material. There are three phases present – solid, liquid (or leachate) and gas. The solid waste forms a pore space that contains the liquid and gas fluids. A small fraction of the solids is bio-chemically reactive. These reactions break down the solids to form leachate and gas products. The solid degradation causes settlement of the solid phase, and flows in the gas and leachate phases – usually resulting in unwanted emissions from the landfill. Waste degradation, gas and liquid flow, and waste settlement are therefore the primary landfill processes of concern.

Waste degradation

Gas and liquid flow

Waste settlement

Process of waste degradation

Waste is a complex porous material in which landfill processes such as bio-chemical degradation take place. The material has a solid phase – the waste itself – which contains within its pores a two phase gas and liquid fluid.

The degradation of the solid phase in the waste takes place as the result of chemical reactions. These reactions release gas and dissolved chemical compounds into the gas and liquid phases contained in the pore space of the solid phase. ...MORE

Chemical equations that control waste degradation

The chemical degradation stoichiometric equations represent the pathways along which the chemical degradation reactions take place. These equations link together the chemical compounds found in a landfill as the result of waste decomposition. This means we need to be able to convert the description of the waste in terms of the more familiar characteristics of Food, Green waste, and so on, to a description in terms of chemical compounds (Protein, Fat, Carbohydrate and Glucose).

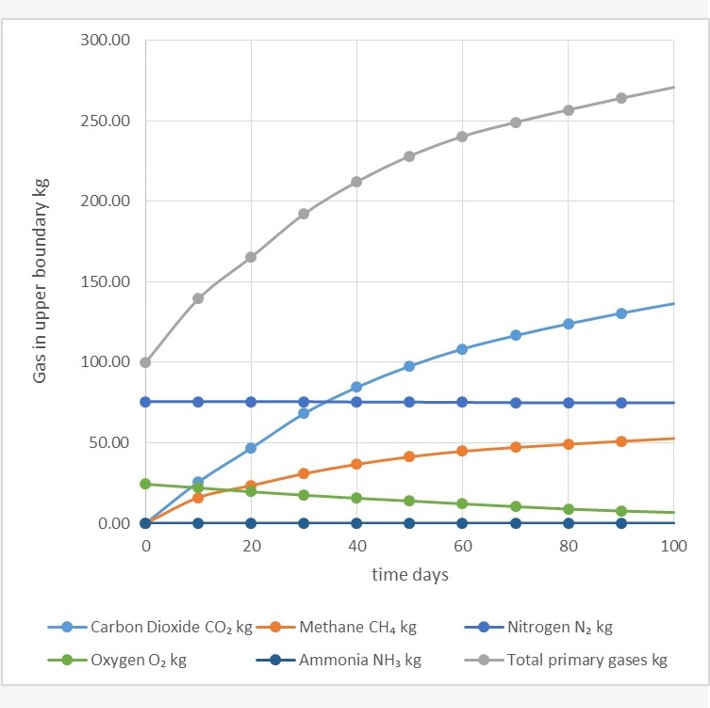

The stoichiometric equations can be used to estimate the quantities of leachate and gas consumed or produced as the waste degradation reactions proceed. The equations are also used to describe the interaction between the dissolved waste compounds and the bacteria in the waste that control the rate at which the reactions take place. ...MORE

Landfill leachate and gas flow

The generation of liquid and gas, as the result of waste degradation in the landfill, sets up pressure gradients in the waste pore-space network. Flows take place in both the liquid and gas phases in response to these pressure gradients.

In our landfill process model standard unsaturated liquid and gas flow theory based on Darcy’s Law is used to model these flows. This requires models to relate relative permeability and capillary pressure to moisture content. LDAT uses the van Genuchten relationships for these models.

In the case of waste materials it is particularly important to model the strong relationship that exists between hydraulic conductivity and depth in a landfill. The Powrie and Beaven relationship is used for this purpose. ...MORE

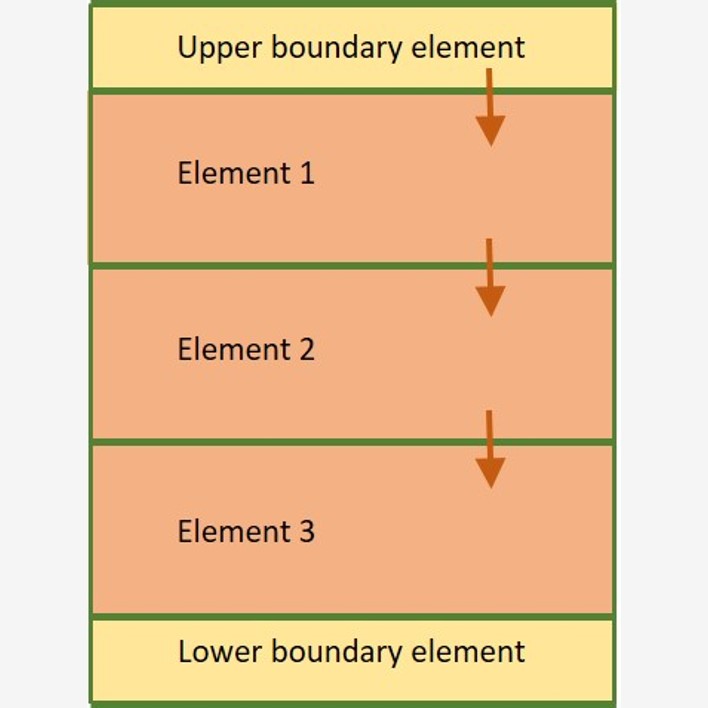

The liquid and gas flow algorithm used in landfill process constitutive equations

The LDAT landfill degradation and transport model contains a liquid and gas flow sub-model. The LDAT liquid and gas flow algorithm is the calculation procedure that LDAT uses to solve the landfill process analytical constitutive equations. This is a finite difference algorithm that operates upon a framework of rectangular representative elementary landfill waste volumes. Multi-phase multi-component landfill processes models like LDAT are used to support the design of landfill management and engineering systems that implement leachate flushing /recirculation, aeration, and gas extraction and collection. These models have the capability to represent the multi-component two phase flow of liquid and gas through the pore space of the solid phase of the waste material. ...MORE

In our landfill process model, the settlement of the solid phase is assumed to be one dimensional, taking place only vertically within a particular Stack of LDAT elements. It is further assumed that the Stack settlement reflects the relationship between the effective stress in an element, and the dry density of the waste in that element, and does so in accordance with the relationship proposed by Powrie and Beaven. Settlement due to creep is not taken into account.

Changes in the solid phase dry density in each element, due to dissolution and bacteria growth or death, are calculated by the model's calculation engine, and then vertical transfers of solids are made between elements to align the dry density with the current effective stress using the Powrie and Beaven relationship. Calculations are made starting with the element above the lower boundary element and then, working up the Stack, finally calculating the top-up mass of inert solids required to be taken from a stock of inert solids that is made available in the upper boundary element of the Stack.

The settlement at any time is then estimated by dividing the total inert mass of solids taken from the upper boundary stock of inert material at that time, by the horizontal cross-section area of the Stack, and by the current value of the dry density of the solids in the upper waste element. ...MORE